EXAMPLE OF THE LIFECYCLE OF A PLASTIC BOTTLE

1. EXTRACTION

The extraction process consists in the drilling or fracking of oil and natural gas. If you’d like to find out what the differences in these two processes are, click here.

2. REFINEMENT AND CRACKING

Raw oil is then shipped to a refinery that is going to derive the building blocks of plastic: ethane (oil) and propane (natural gaz), which are then chemically broken down at the cracking plant into hydrocarbon monomers: ethylene and propylene. These monomers are then chemically bonded into chains called polymers. There can be many different combinations of monomers and therefore, we can find all sorts of polymers that have different characteristics and properties.

3. PROCESSING AND MANUFACTURING

During this phase, additives are added to the polymers to reach the desired plastic characteristics, such as color, melt flow, protection from outside factors (sunlight, heat, bacteria, etc.), flexibility, durability, etc.

Manufacturing processes include:

- Extrusion: Plastic pellets get melted and then pushed into a small opening to shape the desired finished product. This process is used to make plastic bags for instance.

- Injection Molding: Plastic pellets get melted and the resin is forced at high pressure into a closed mold. Once cooled the mold opens up to release the finished product. This process is used to make yogurt and butter containers for instance.

- Blow Molding: This process can be used either with extrusion or injection molding. The semi-molten plastic pellets are injected into cooled molds, compressed air is then blown into the plastic to make it a hollow product. This process is used to make milk bottles for instance.

- Rotational Molding: Plastic pellets are placed in a closed mold in a machine that heats the pellets to melt and at the same time rotates around two axes, eventually allowing to create a hollow product. This process is used to create large toys, kayaks or furniture.

4. DISTRIBUTION, CONSUMPTION & END OF LIFE

- The final plastic product, 40% of the time a single-use product, is then shipped to the company that will use it as packaging, or final product.

- It is then shipped to the retail distribution center (and then to the retail location if sold in a retail shop). It can also be shipped to a fulfillment center that fulfills online orders to be shipped a final time to the final consumer.

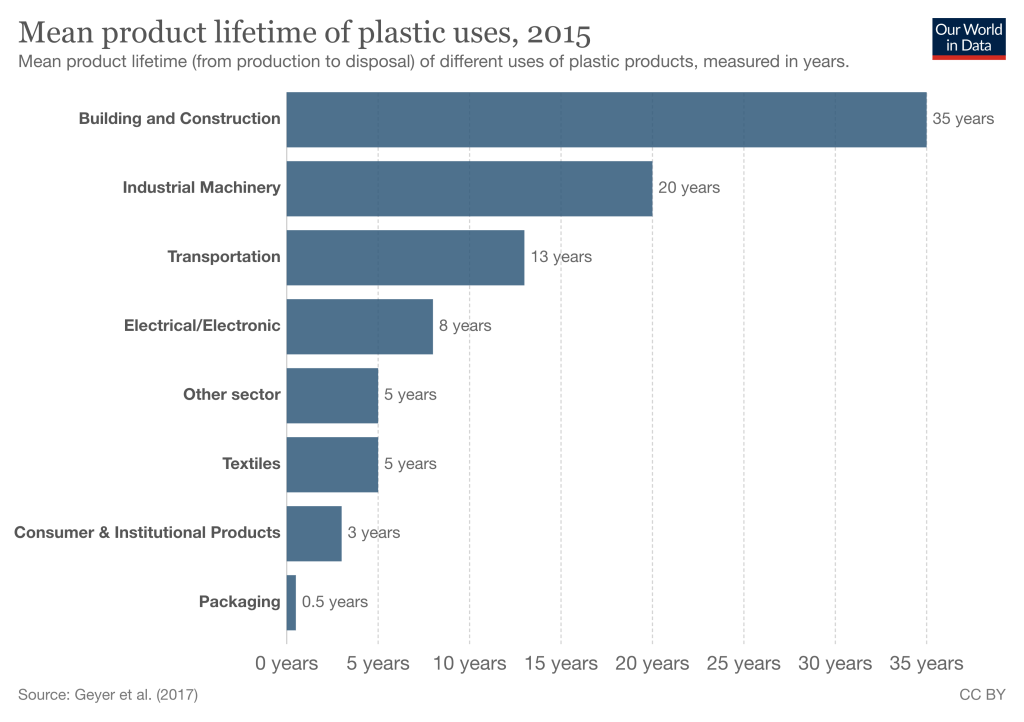

- The final consumer uses the item for a certain period of time: See graph from Our World in Data below.

- There are three main end of life possibilities for plastic:

- Landfill

- Leakage

- Recycling